Fixtures

A fixture is a work-holding device used to securely locate in a specific location or orientation and support the work, ensuring that all parts produced using the fixture will maintain conformity. Fixture improves the productivity by smooth operation and quick changeover from part to part.

Our Projects

Customer Requirement

De-bottleneck the process constraint to improve the capacity utilization. In the Same machine another tool outsourced due to capacity constraint.

Current Process

Trimming & inspection of plastic moulded part is done off-line MANUALLY.

GEENO’s Proposal

A cooling fixture is designed to control the warpage in the plastic moulded part. Trimming fixture is designed to removed the flashes online within the cycle time of process.

Offered Customization

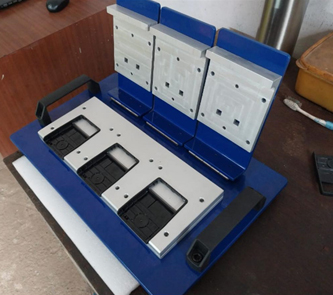

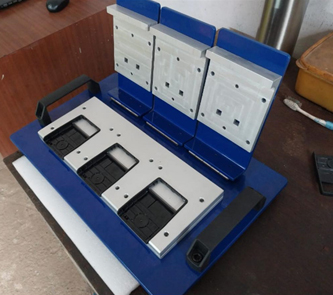

Cooling Fixture to Control Warpage

Moulded part is kept in cooling fixture and

rotated. After full rotation, the part warpage is controlled (1 part / 1 fixture)

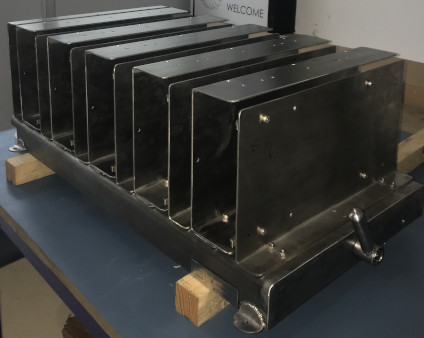

Trimming Fixture

Benefits

Adhesive Curing Fixture

For holding the plastics moulded parts to retain the profile of rubber gasket after adhesive application.

Pin Insertion Fixture

Pneumatic operated fixture for inserting metal pin in the plastic moulded part

Customer Requirement

To place the brake disc into heater zone.

Current Process

Manually pushing the brake disc into the heater zone.

GEENO’s Proposal

A tilting fixture is designed to place the brake disc into the heater zone.

Hot Disc Tilting Hub

Customer Requirement

Develop a fixture for retaining rubber seal in its position (3 dimensional seal) after adhesive application.

Current Process

New development

GEENO’s Proposal

Single fixture for retaining the rubber seal from all directions

Seal Retaining Fixture

Customer Requirement

Clip should be assembled in the rear side of the part with reduction in assembly cycle time.

Current Process

New development

GEENO’s Proposal

Develop a fixture with assembly on the rear side of the part (Clip assembly at the rear side of the part) – Cycle time achieved as per the target.

Clip Assembly Fixture

Customer Requirement

Automation for Riveting process (28 points)

Current Process

Manual holding of part on rotary fixture and riveting – Manual part holding work content is more than riveting process

GEENO’s Proposal

Develop a fixture eliminating manual part holding – Part holding orientation changed from vertical to horizontal plane for work content reduction and operator fatigue. Achieved target productivity without automation.

Fixture for Riveting Process

Customer Requirement

Worktable with ESD compliance of 10^6 ohms

Current Process

New development

GEENO’s Proposal

Manufacturing of table with ESD compliance powder coating. Audited and certified by 3rd party lead auditor

ESD Worktable