Who We Are

An Engineering Solution Company for all Manufacturing Processes

GEENO TECH SERVICE is the passionate entity that is started to serve the manufacturing industry of any field. The main idea behind this start-up is to assess and analyse the current requirement of the customer and assure the system that is benefiting the customer in terms of Productivity, Quality, Cost and Safety.

- 20+ Years Experience in Manufacturing, Tier1 & Tier 2 Industries

- 4 greenfield projects & 2 brown field projects

- 250+ New Product Industrialization

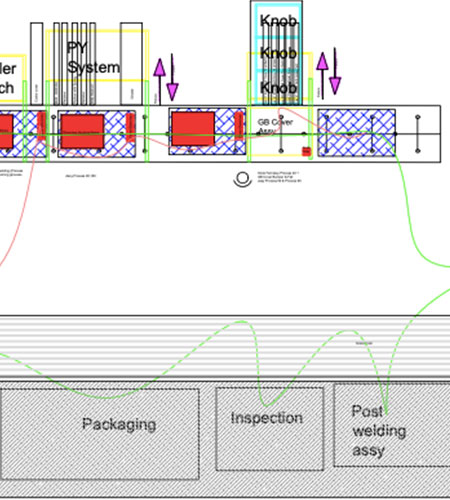

- Plant and Process layout

- safety process & Traceability

- Data analysis- AI based

- Localization- new equipment development

- JIT-JIS Assembly line design-Line balance

Services

We are Qualified & Professional

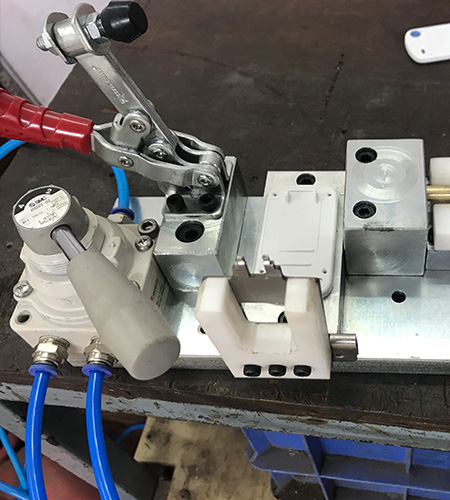

Fixtures

A fixture is a work-holding device used to securely locate in a specific location or orientation and support the work, ensuring that all parts…

Read More

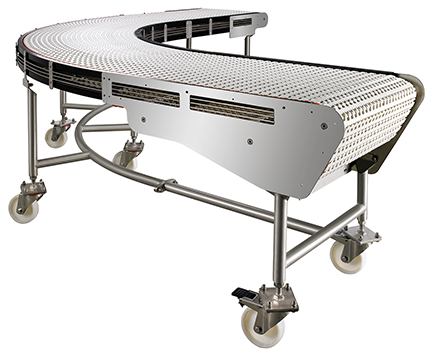

Material Handling Equipment

Material handling equipment (MHE) is any tool used for the movement, storage, control, and protection of materials, goods and products throughout the process…

Read More

Lean Plant Layout Design

Lean plant layout focuses on value streams, all value-added steps from raw materials until the delivery to your customer. Lean layouts are more likely to combine…

Read More

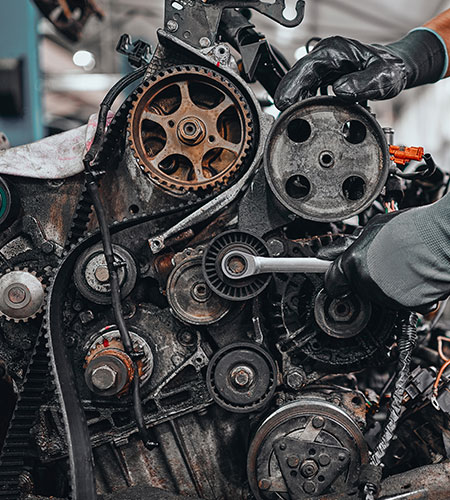

Allied Services

Installation of machines, conveyors & other manufacturing systems, Repair & retrofitment of machines, Robots, Pick & place systems etc…

Read MoreGet an Estimate For Your Service

Products

Metalworking Fluid Product

Metalworking operation demands the use of right machines, precision cutting tools and right selection of metal working fluids to achieve the best results. We at GS Caltex understand the key aspects of this operation to provide you with the best metalworking fluid solutions to achieve a hassle-free operation and obtain maximum efficiency. GS Caltex metalworking fluids have been developed considering every machining operation is uniquely characterized by its own input, output and process parameters to offer you with the best possible solution for your operation.

We are the authorised distributor for GS CALTEX Metal working Fluids

- Water Soluble Cutting Oil

- Neat Cutting Oil

- Rust Preventive Oil

Project

Our Project Approach

1. Customer Requirement

Understand the customer requirement by plant visit, technical discussion with the team

2. Project Report

A brief project report will be submitted to the customer with the current level and the customer expectation / requirement of the project. Technical concepts / clarifications in the technical specifications / drawing submission will be shared in this report along with the indicative price

3. Detailed Technical Discussion

Detailed Technical Discussion will be held with the customer for finalising the understanding on the technical assumptions / concepts

4. Commercial Discussion

Finalising the commercials for the execution of the project

5. Installation / Commissioning

The system will be supplied and installed at the defined lead time at the customers’ identified location

CUSTOMERS

Our Clients